GLO Effex Strontium Aluminate based glow in the dark powder also called glow pigment or super phosphorescent powder is a new type of environmentally friendly alkaline earth aluminate pigment that is non-toxic and non-radioactive. The pigment particles are charged by most any visible light or ultraviolet light. The pigments then release energy in the form of visible light for 10 to as much as 24 hours. These pigments provide a duty-cycle operation with a very high ratio of glow time to charging time required. The glow intensity and after-glow time are over 30 times greater than traditional zinc sulfide or other commonly sold retail store products that you see.

The basic structure of the particle is crystalline, which has a tremendous capacity of absorbing, storing, and emitting light. The crystals absorb any ambient light, including regular indoor light. This provides incredible potential in safety, novelty, and industrial applications.

Basic Guidelines For Using the Super Phosphorescent Pigment.

More powder, higher percentage will produce brighter, longer glow.

Use a white, or light color as a background for best results. Any color other than white will diminish glow.

Use the clearest vehicle possible. Any pigment in the vehicle will decrease the brightness and length of glow.

The thicker (to a point) the layer of Super Phosphorescent Pigment will produce longer and brighter luminosity.

Try to prevent moisture in the manufacturing process.

Do not use vehicle with high acidity.

Do not grind the Super Phosphorescent Pigment, it will destroy the crystal structure and therefore decrease luminosity.

Ratio of Super Phosphorescent Pigment to medium is from 10% to 50% by weight depending on application.

The most frequently asked questions in regards to Glow Powder are:

What can I do with the powder?

Let your imagination go wild! You can do practically anything with our versatile glow in the dark pigment! It is safe for the application in consumer products such as manicures, woodworking, concrete work, grout, clothing, shoes, caps, watches, novelties, tackle & sporting goods.

It has excellent results in the fields of building, decorating, traffic vehicle, military installations, fire emergency system, & escape route signs. Literally endless uses and endless ways to use.

The pigment can be mixed with a variety of transparent resins & binders including but not limited to acrylic resin, paraffin, PU Resins poly acylamonia resins, amino resins, glues, plastics-PE, PP, ABS, PVC. And, of course all your craft Mediums! Candles-gel/wax, ceramics, ceramic glaze, fabric paint, oil paint, acrylic paint, nail polish, hair gel, caulking, acrylic/gel nails, glass, rubber, etc.

Is the Glow Powder safe for kids?

Yes, the glow powder is non-toxic and non-radioactive & environmentally friendly.

Can I add it to soap & other skin products?

Green & Aqua colors have been tested & are safe for prolonged skin contact. As with any chemical product, there is always the chance of skin irritation, so apply to a test area first.

How do I use?

You basically just mix it with the medium you want to use it with. Powder will not melt and does not dissolve but will be suspended in the medium. You can use the glow powder in just about any application. Mix it with paint, candles-wax/paraffin, hair gel, fishing lures caulking, glue, plastic, inks, wax, plastisol, etc. Limitations are endless.

How much do I need?

This is a difficult question because it depends on vehicle used, process and application. On average 10%-50% by weight is the best ratio for mixing Glow Powder to a vehicle. The percentage depends on how much glow is desired. If the base is a color other than white you may need to add more Glow Powder to achieve desired results.

(Amounts shown are for Max Glow)

1oz - 14 grams pigment

1 Pint - 1/2 lb pigment

1 Gallon - 2 lb pigment

1oz = 28 grams

1kg = 2.2lb

One kilogram of dry Glow Powder can cover an area roughly 3.3 square meters or 12 square feet.

The amount of powder to medium will depend on how much glow desired, cost effectiveness, type of application method etc.

The Basic Guidelines dictate from 10% to 50% by weight. If you are producing a low cost item, then a lower percentage would work best for you. If you are screen printing shirts and want to make only one pass, a higher percentage would work better.

Generally, the higher the ratio of glow in the dark powder to medium, the brighter the glow and potentially a longer glow. Please also consider the color of the surface to which the medium is going to be applied. Experimentation will be the best method of determining ratios after following the guidelines.

Can powders be mixed to create different colors?

No.

How do I charge the powder?

Glow powder responds best to light sources rich in UV rays such as sunlight, black lamps and halogen lamps. Tungsten lamps (typical household bulbs) take longer to recharge the pigment because their UV output is low. Fluorescent lamps, which are rich in UV, provide faster excitation when Glow Powder is placed near them.

Sun light - 5 minutes / UV light (Black light) - 5 to 10 minutes / Normal light - 20 to 30 minutes. Sunlight is the best source for charging the products, but practically any light source will do and the length of time to charge will depend on the intensity and the amount of UV rays emitted. Black light is a great source of UV light.

How many times can I charge it?

You can charge the pigment OVER AND OVER indefinitely! Shelf life is a minimum 15 years.

What color are powders in daylight?

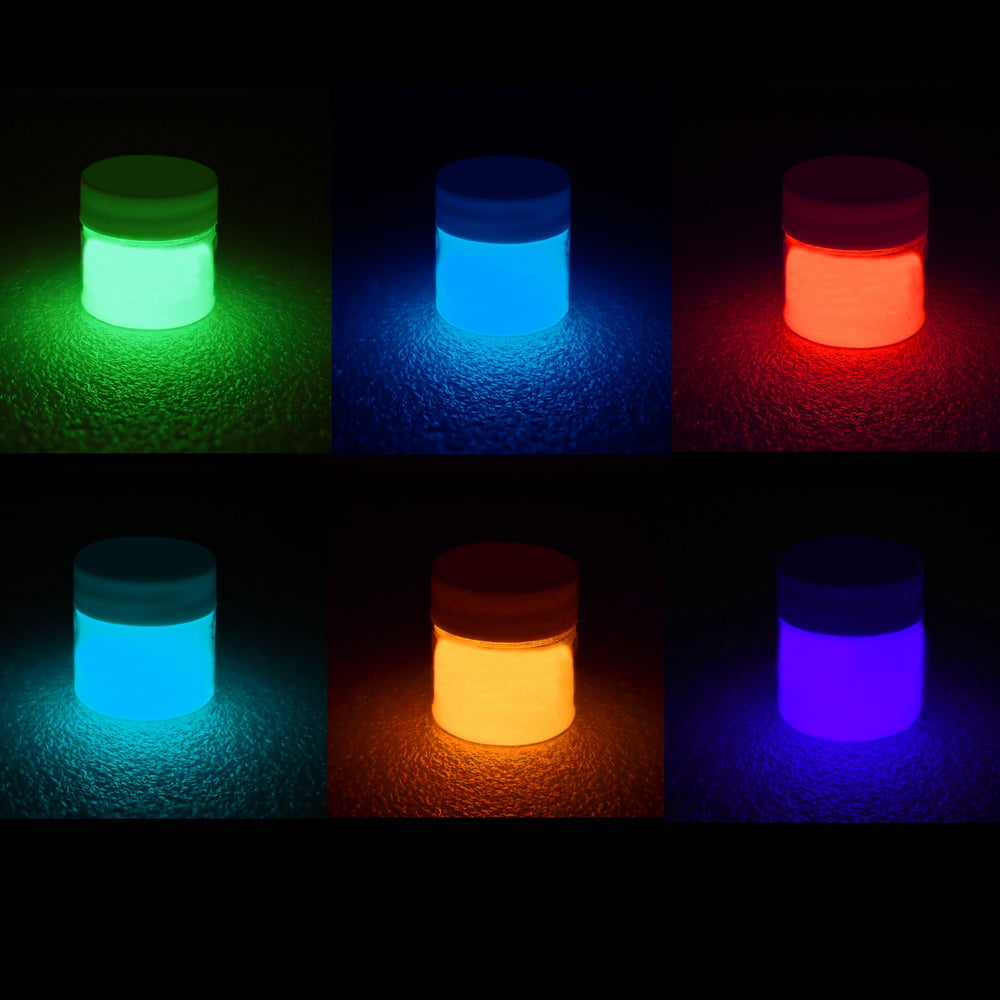

Green is a pale off white/yellow and Blue and Aqua are all a pale off white powder. Purple, Orange, Pink and Red are white.

Will constant sunlight exposure affect the glow powder?

GLO Effex Super Phosphorescent Glow in the Dark pigments are very stable outside and can last many years.

Can you put Pigment in water based medium?

Yes, All our powders can be used for this application.

Do the different colors glow different times?

Yes. Green is the brightest and longest. Aqua glows the second longest. Blue is close behind, Purple up to 4 hours, Orange and Pink up to 2 hours and Red about 30 minutes.

What is first aid treatment? Although it is free from the heavy metals and any of radioactive substances, it is recommended to wear the dust mask or other safety devices, when handling our products. May cause irritation of nose, throat, eyes & skin. Wash with water when your skin or eyes are exposed to our products. Keep the products away from moisture and seal it when not in use. Please see the SDS info on our website.

How does our new generation powders compare to the old glow-in-the-dark pigments?

There are two basic glow-in-the-dark (GID) materials. The older style that has been around for many years is Zinc Sulphide with Copper as an activator and THE NEXT GENERATION Strontium Aluminate that GLO Effex Sells.

The afterglow is about 10 times longer than conventional pigments and about 10 times brighter. The excitation wavelength is very broad 200-450nm. We only carry the latest generation powder.

Do powders have an odor?

All our pigments are odor free

Do you offer wholesale pricing?

Yes! Please email us at sales@gloeffex.com

How does your pigments compare with other companies?

Unfortunately many companies are selling lower grade pigments with fillers added, as the brightest pigments around. We back up our products with complete data & technical Specs on every product so you can make an informed decision.

Additional Information:

Encapsulated vs. Not Encapsulated - All GLO Effex powders are encapsulated. Encapsulated glow in the dark powders have a protective coating over the powder particle that makes it waterproof, while the non-encapsulated powders do not have the protective coating. Encapsulated = WATERPROOF vs. Not Encapsulated = NOT WATERPROOF.

My powder has a tendency to be grainy after my paint dries. Is there any way to make it completely dissolve but still give a glow effect?

Hello I was wondering can I add this to my hair dye or conditioner and make a paste out of it. Mouse to add it to my hair. I am going to be doing my hair like rainbow bright and not because it’s almost Halloween. But because I have been saving my xtra cash for months to buy all the hair dye because I really really like it. So can I add it to those and make my hair glow. And howl long would it last for if I am able to. Thank you and I hope you have a beautiful day.

Hi, I have a question, I have bought some Glow powder in my own country and now I like to use them in my painting, how should I prepare the powder for painting? can you guide me?

Thanks

Hi I would like to know how can I use it with marble ?